This Peinert 26 deck was badly damaged by a falling tree. As is often the case, a previous repair complicated the shell restoration we performed. In order to keep the Peinert close to its original weight, we had to remove and replace a substantial section of the damaged foredeck.

In the first phase of the shell restoration, a mold was made of the crushed deck section from another sound Peinert, and a new deck section was made. The photo shows the process making the mold of laid up fiberglass with cross deck stiffening ribs to hold the mold’s shape .

Peter has the mold taken from a friend’s undamaged Peinert in his left hand and the new deck part that was pulled from it in his right hand.

Deck removal gave access to the fractured interior hull laminate and allowed us to reinforce it with clamped temporary stiffeners and lightweight carbon fiber and epoxy.

Peter has trimmed the new deck part and is checking its fit in place.

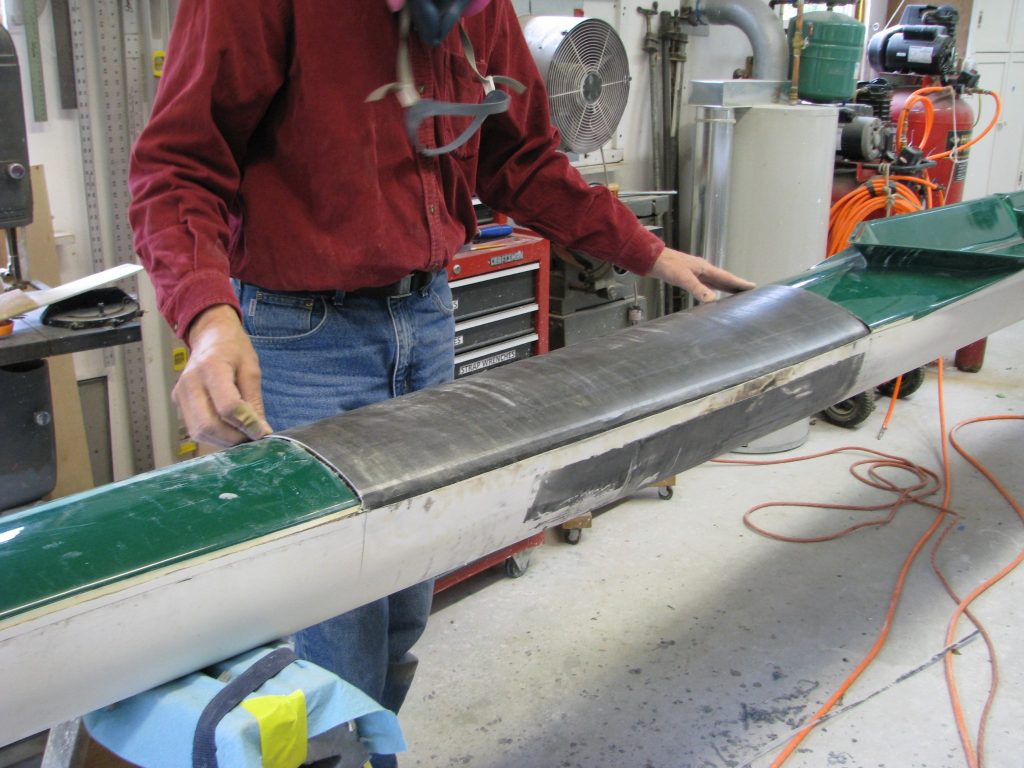

Peter is using a 3M Rigid Long Board to longitudinally board sand fairing compound to perfect hull lines.

The flawless finished deck with 3m striping tape

A new Peinert 26 decal to go with the good-as-new shell.